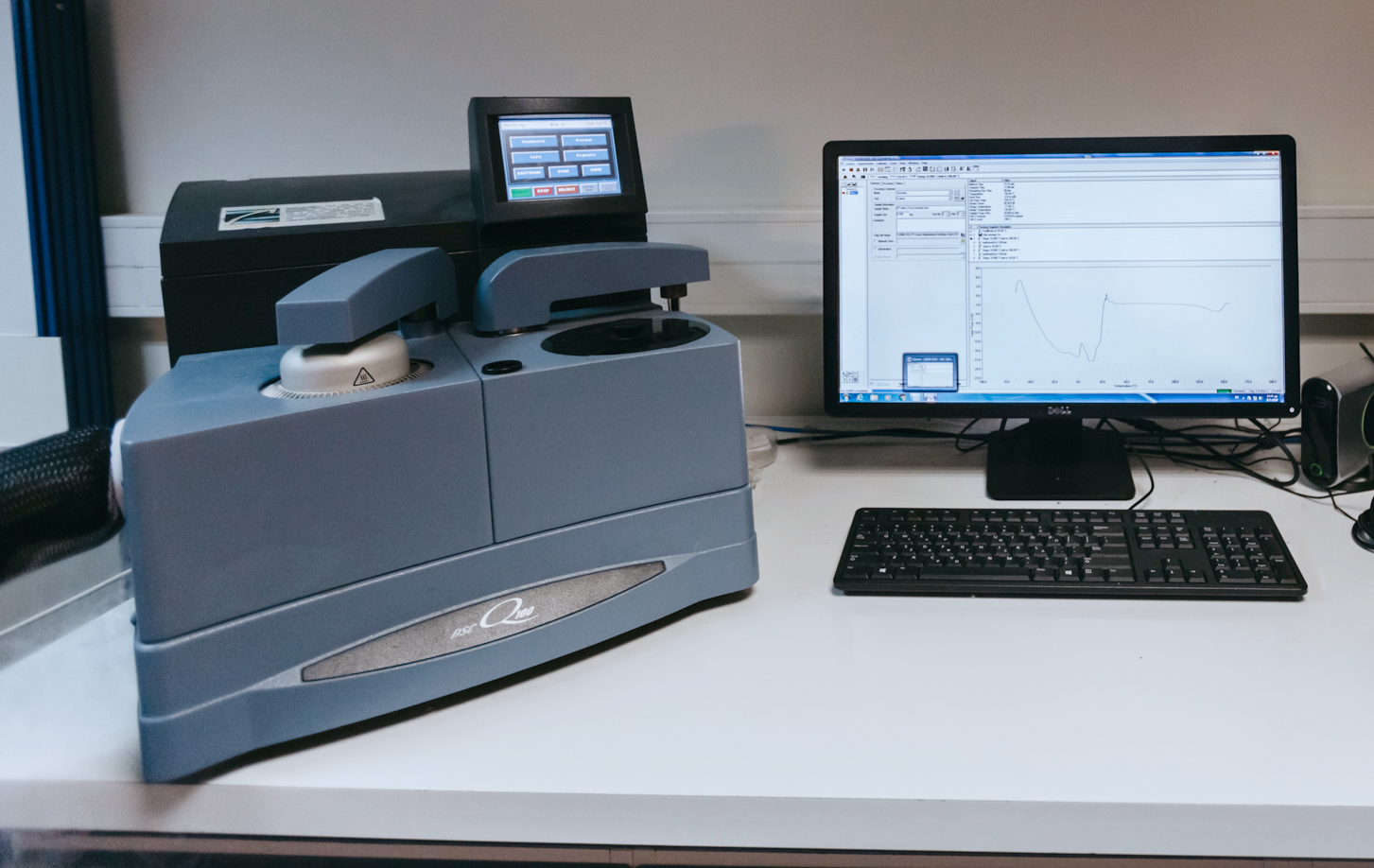

Instrument

Differential Scanning Calorimetry (DSC)

According to the ASTM standard E473, DSC is a technique in which the heat flow rate difference into a substance and a reference is measured as a function of temperature, while the sample is subjected to a controlled temperature program. It uses the temperature difference developed between the sample, and a reference for calculation of the heat flow. An exotherm indicates heat flowing out of the sample, while an endotherm indicates heat flowing in.

If a temperature modulation is overlaid on a linear heating or cooling rate the technique is then called Modulated temperature differential scanning calorimetry (MDSC). An MTDSC experiment can not only generate the total heat flow similar to the heat flow obtained in conventional DSC but also separate the total heat flow into its reversing and nonreversing components. The total heat flow is the sum of the thermal events and is generally equivalent to the heat flow seen in conventional DSC. The reversing heat flow is the heat capacity component of the total heat flow.

Characteristics

According to the ASTM standard E473, DSC is a technique in which the heat flow rate difference into a substance and a reference is measured as a function of temperature, while the sample is subjected to a controlled temperature program. It uses the temperature difference developed between the sample, and a reference for calculation of the heat flow. An exotherm indicates heat flowing out of the sample, while an endotherm indicates heat flowing in.

If a temperature modulation is overlaid on a linear heating or cooling rate the technique is then called Modulated temperature differential scanning calorimetry (MDSC). An MTDSC experiment can not only generate the total heat flow similar to the heat flow obtained in conventional DSC but also separate the total heat flow into its reversing and nonreversing components. The total heat flow is the sum of the thermal events and is generally equivalent to the heat flow seen in conventional DSC. The reversing heat flow is the heat capacity component of the total heat flow.

Services

Bruker D8 Advance

CuKa radiation, Bragg-Brentano geometry (2θ:0-1600)

1D & 0D detectors

Parallel beam optics, Knife edge collimators, Soller slits

Diffracted beam monochromator

Thin Film attachment

High-temperature furnace (300-1173K)

Appropriate software for instrument control and analysis

Sample Properties

Sample quantity: 5-20mg